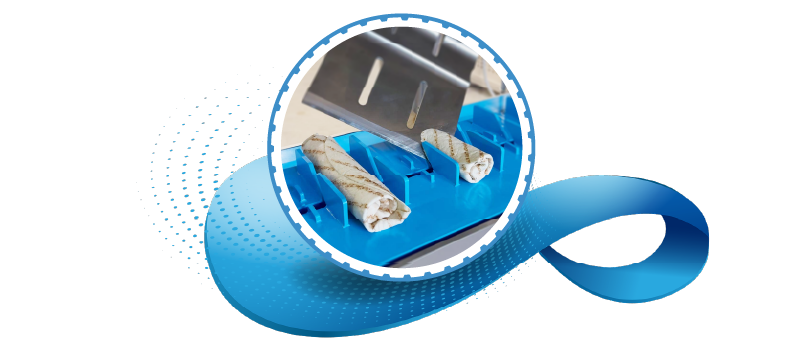

Semi-automated wrap and sandwich production in high-care areas requires the strictest hygiene standards. These products are ready-to-eat and go directly from packaging to supermarket or petrol station shelves, which makes them particularly high risk for contamination — including Salmonella, Listeria, and cross-contamination during recipe changes (e.g., gluten-free).

Our Conveyor Belt Advantage:

Our belts were chosen for this production line because they are made of a high-quality homogeneous compound. Unlike conventional belts:

✔ No fabric layers or plastic parts that could break and contaminate food.

✔ Smooth, non-porous surface ensures effective cleaning and wash-down.

✔ Designed for easy removal and hygiene control

✔ Ideal for swap testing during recipe changes

Designed for uncompromising hygiene, these belts help manufacturers achieve the same rigorous standards trusted by cheese, salad, and sandwich producers worldwide — delivering safety, reliability, and confidence at every stage.

Supported by advanced manufacturing capabilities, we deliver tailor-made solutions that meet every OEM specification with precision, quality, and efficiency.

Looking for a belt that fits your exact process needs?

Tell us more by filling out our technical questionnaire — our team will reach out with the ideal solution.

Explore more Volta Belting solutions for the bakery industry’s food conveyor belts.