TRANG CHỦ » Fabrications

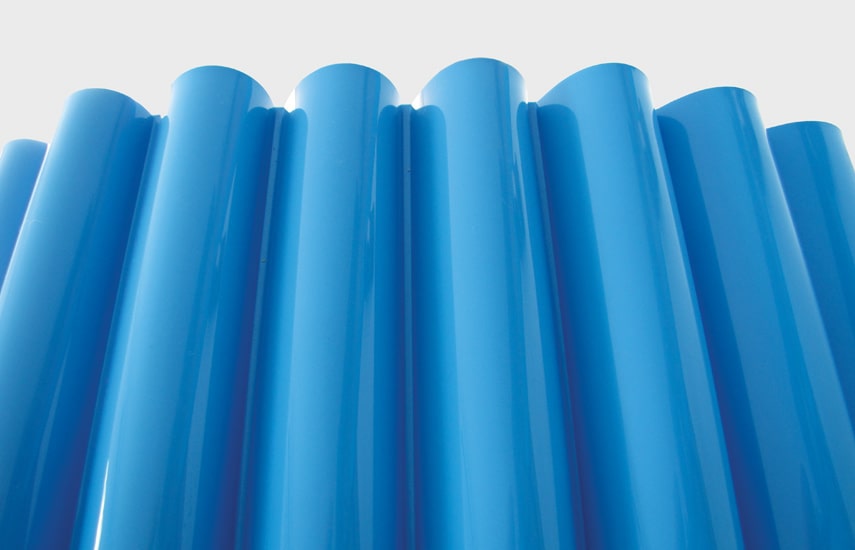

Fabrications

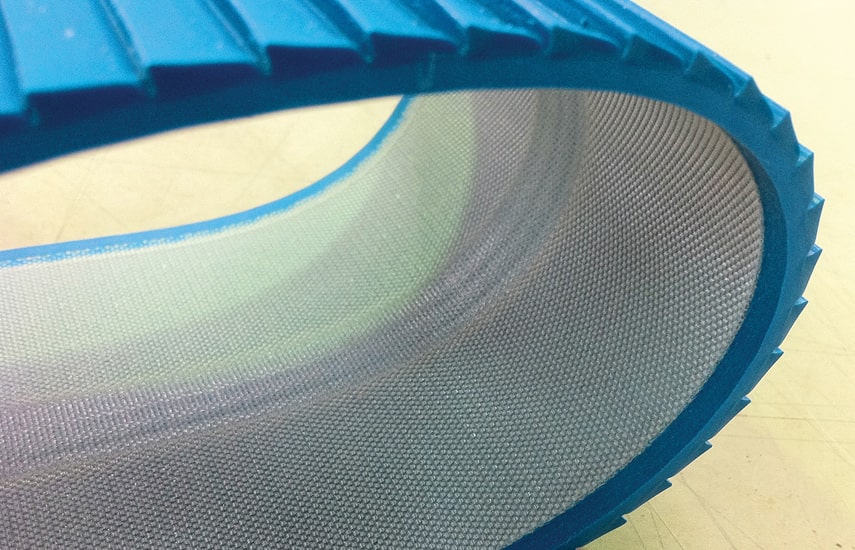

‘Fabrication’ is the term used for the cutting, welding, and splicing custom additions to specific belts from our thermoplastic belting materials or profiles.

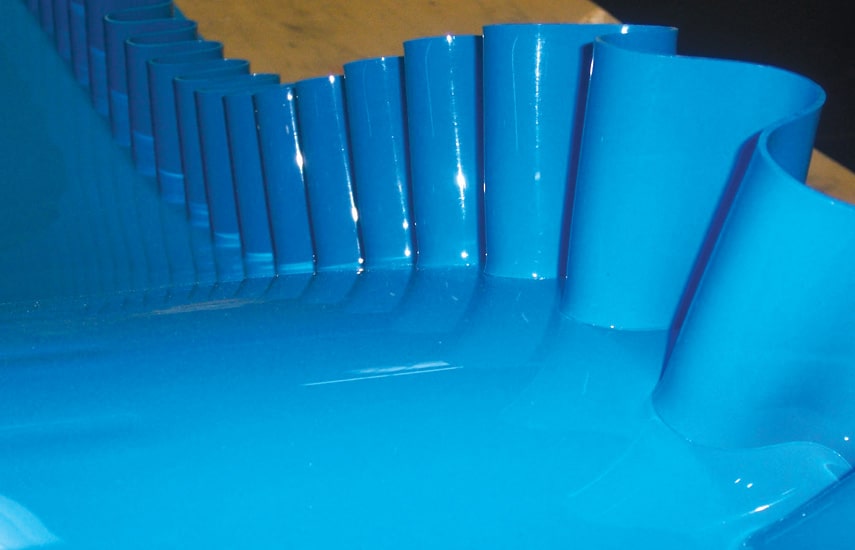

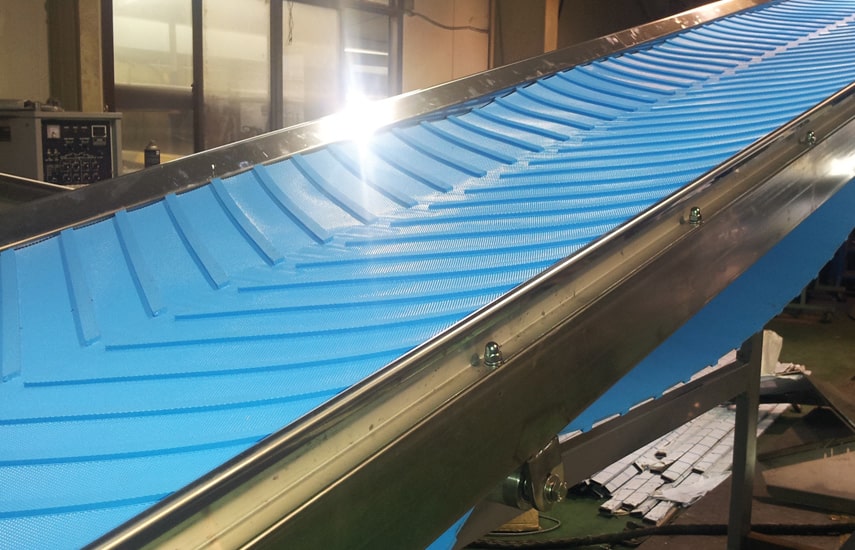

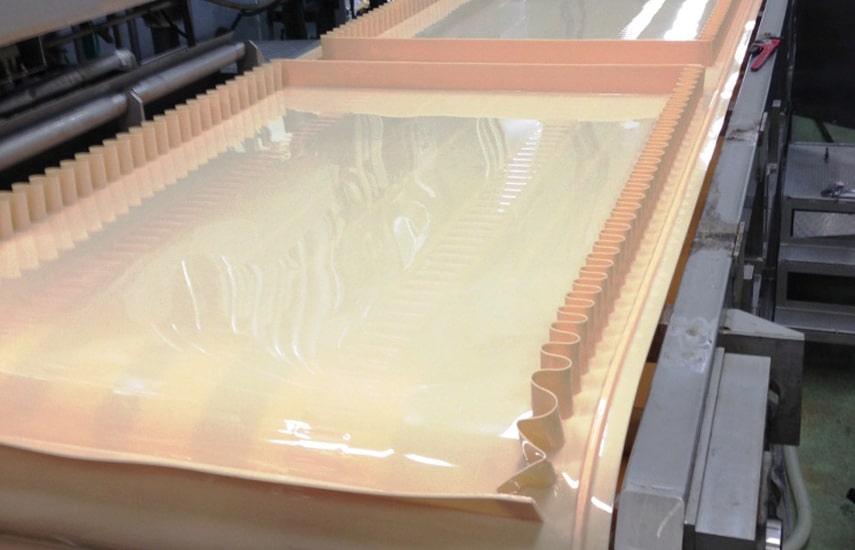

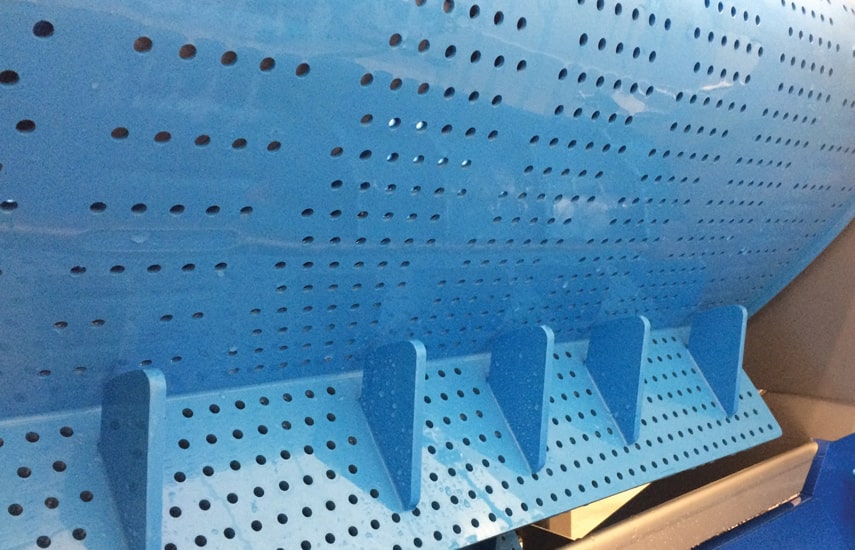

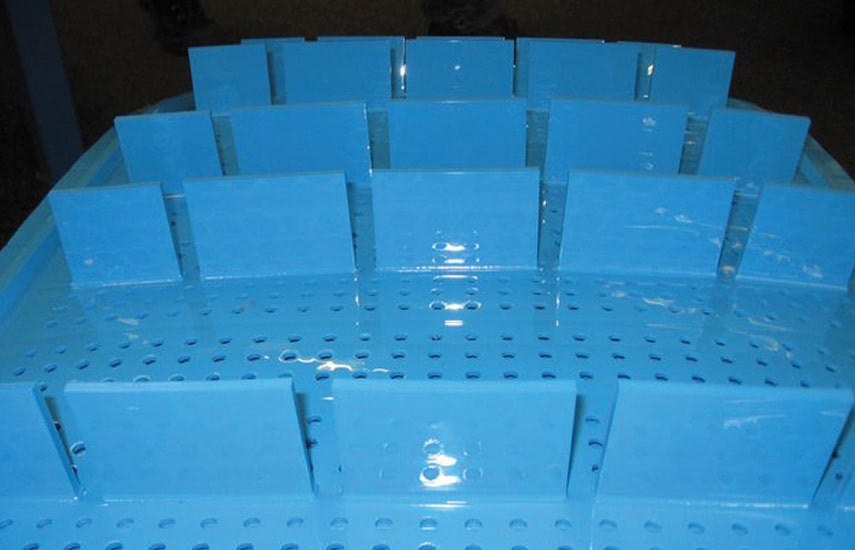

Volta fabrications are processed with high frequency (HF) or heat welding techniques. Most of our TPE products are compatible one with another. Our fabrication centers can hand-weld custom-designed features to high performance belts to accommodate special product requirements such as the retention of cut vegetables, whole fish, loose cereals or IV pouches.

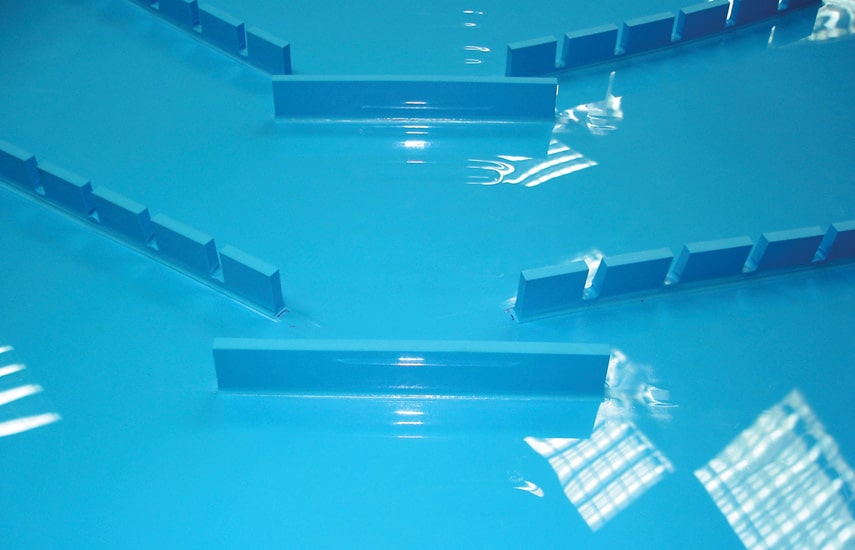

We treat several fabrication styles as standards; this includes flat, angled, and scooped flights/cleats, top and bottom guides and welded side wall containment.

Technical Support

Our trained staff review designs daily, to ensure that our belts conform to the demands and specifications of the conveyor system used. Fabrications are a major part of this review and we have inventive and reliable methods for solving problems where conventional belting will fail. Our co-workers and belting partners share a passion for providing service-based added-value solutions for conveyor belt replacements as well as for new processing systems.

Predictable Hygienic Engineering

Dedicated OEM customers use our throughput calculations to optimize conveyor designs, comparing possible dimensions, shapes and spacing of cleats, providing end users with economic conveyor systems. The finish on our fabricated features is hygienic and suited to the food processing industry. The savings Volta flat belting can provide in cleaning, costs of disinfection and downtime, are game changers.

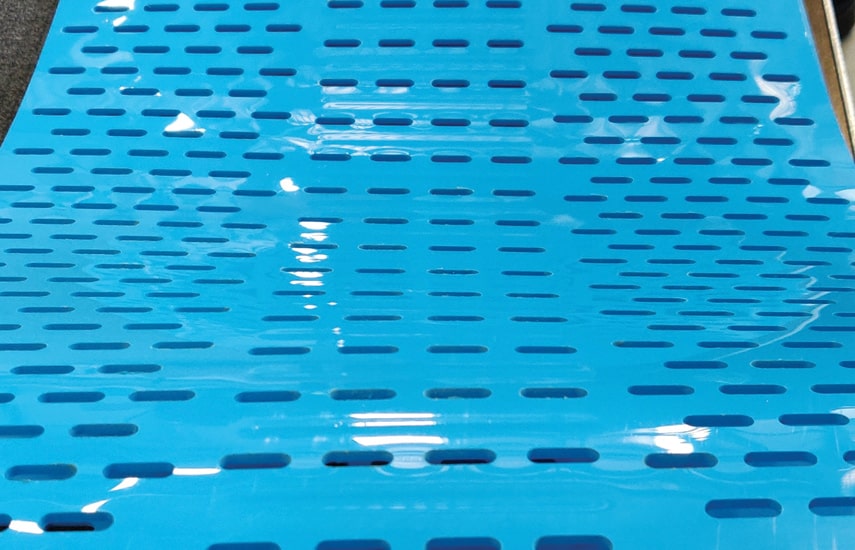

Perforations in belts can provide drainage or the circulation of air. Volta fabrication centers use hygienic cutting technology to perforate automatically via computer generated designs, calculated to give the maximum use of the belt while maintaining sufficient belt operating strength.

Custom Designed Fabrications

Some of the unique examples of custom fabrications described below, illustrate the versatility of the material and the solutions that our customers and workshops have come up with;

flat side walling designed to reduce belt width and increase cleat length in special cases

watertight compartments on belts used for offal containment

cushion type pads used to protect soft fruit from bruising

adapted cleat forms used to hold products in place during individual processing.