The seafood processing industry faces some of the toughest hygiene challenges in the entire food sector. High moisture, low temperatures, organic residue, and complex product flows create the perfect conditions for contamination if hygiene is not managed correctly. Maintaining a clean and safe process is not only essential for protecting consumers, it also influences yield, equipment lifespan, operational efficiency, and brand reputation.

Today’s most successful seafood plants have something in common: they rely on smarter hygiene strategies that reduce risk while improving productivity. One of the most effective ways to achieve this is by upgrading to equipment designed specifically for hygienic environments—starting with the conveyor belts that move your product through every stage of the process.

This is where Volta’s hygienic conveyor belts make a measurable difference.

Why Hygiene in Seafood Plants Is So Challenging

Seafood facilities operate in conditions that increase the likelihood of cross-contamination:

- Wet and cold production rooms

- High organic residue (proteins, oils, and biofilm-forming materials)

- Frequent product contact with surfaces and equipment

- Heavy washdown requirements

- Sensitive processing zones (e.g., high-care and ready-to-eat areas)

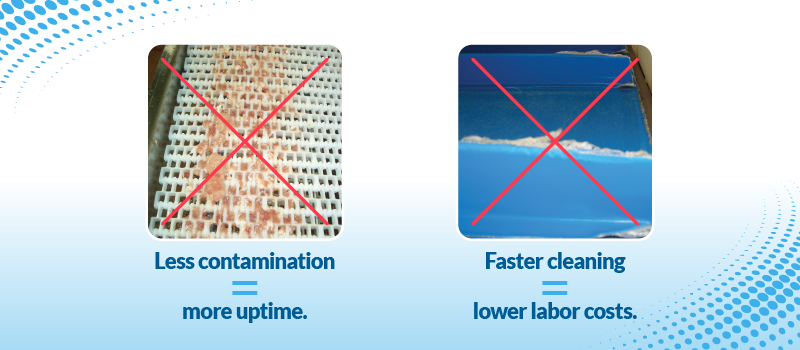

Traditional fabric or modular belts have hidden areas—hinges, pins, layers, and fiber cores where contaminants can accumulate and survive cleaning cycles. A smarter hygiene strategy starts with eliminating those vulnerabilities.

Choose Hygienic Materials That Do Not Harbor Contamination

Volta’s homogeneous thermoplastic belts are engineered with hygiene in mind. Unlike modular or fabric belts, Volta belts are:

- Non-porous

- Solid and homogeneous (no layers, cracks, crevices, or fibers)

- Extremely easy to clean

- Resistant to moisture and fats

- Compliant with food-contact regulations

Because there are no hidden areas where residue can build up, the belts clean faster and more thoroughly reducing the risk of contamination and improving overall plant hygiene.

Reduce Cleaning Time Without Sacrificing Sanitation

Seafood processors know that cleaning can consume many hours per shift. Volta conveyor belts are designed to dramatically shorten washdown time. Many customers report:

- Up to 50% faster cleaning

- Significantly less water and chemical use

- Shorter downtime between product runs

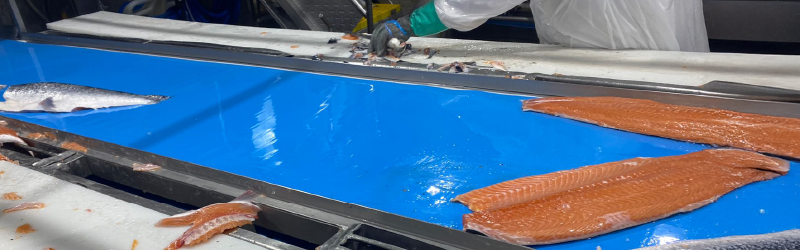

Improve Hygiene in High-Care Areas

High-care zones such as: filleting, trimming, portioning, sorting, glazing, and packing require the highest standards of hygiene to keep the process safe.

Volta belts support high-care operations by:

- Minimizing bacterial harborage points

- Supporting a clean and controlled workflow

- Allowing consistent sanitation even during intensive production

- Enabling easy verification during QA inspections

Their monolithic structure eliminates the typical “weak spots” that can undermine process hygiene in critical zones.

Increase Product Yield by Reducing Belt Damage and Fiber Contamination

Fabric belts can fray. Modular belts can chip, crack, or break at hinges. This can lead to:

- Foreign material contamination

- Product loss

- Costly recalls

- Reduced yield

Volta’s belts don’t fray or shed material, helping maintain product purity and improving overall yield.

Support Sustainability and Lower Operating Costs

Smarter hygiene is not only about safety—it’s also about efficiency. Volta belts help plants:

- Use less water

- Use fewer harsh chemicals

- Cut cleaning labor hours

- Reduce downtime

- Extend the life of equipment

These savings can be substantial, especially in seafood facilities with daily wet-wash cycles.

Conclusion: Smarter Hygiene Starts With Smarter Equipment

Seafood plants that invest in hygienic design see real results: cleaner lines, fewer risks, higher yield, and lower operating costs. Upgrading to Volta’s hygienic conveyor belts is one of the most impactful steps a processor can take to strengthen hygiene and productivity at the same time.

Volta belts are not just an upgrade—they are a strategic advantage for processors who want to stay ahead of food safety demands while keeping operations efficient.