TRANG CHỦ » Special Products

Special Products

Volta offers a range of special belting materials that includes food grade metal detectable (MD) products, low temperature (LT) belting and electro-static dissipative ESD and Anti-Static (AS) products. MD belts have been shown to provide an enhanced standard of care for food processing particularly where recalls of entire batches have occurred due to plastic pieces being found in the processed food. LT material performs well at sub-zero temperatures without cracking. ESD and AS flat and profile belts are used widely in the electronics industry for transporting flat screens, mother boards and other electrical components.

Ready-to-weld fabrication attributes

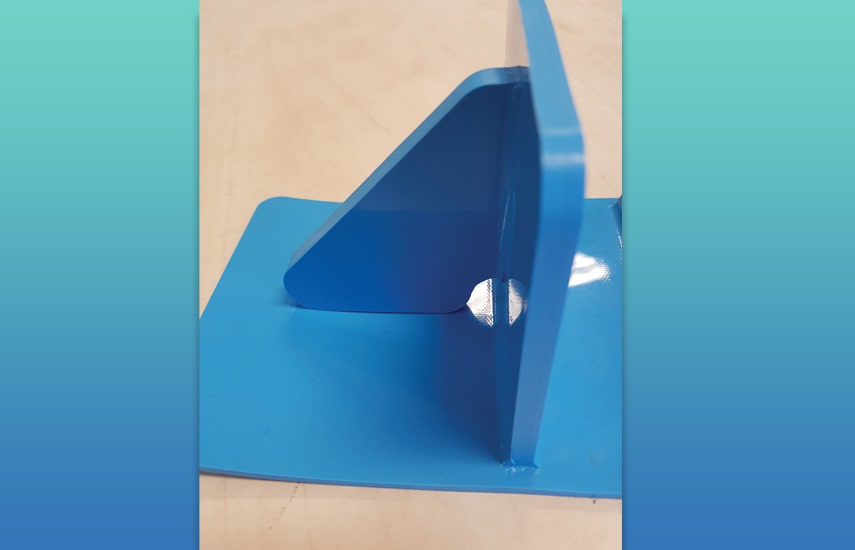

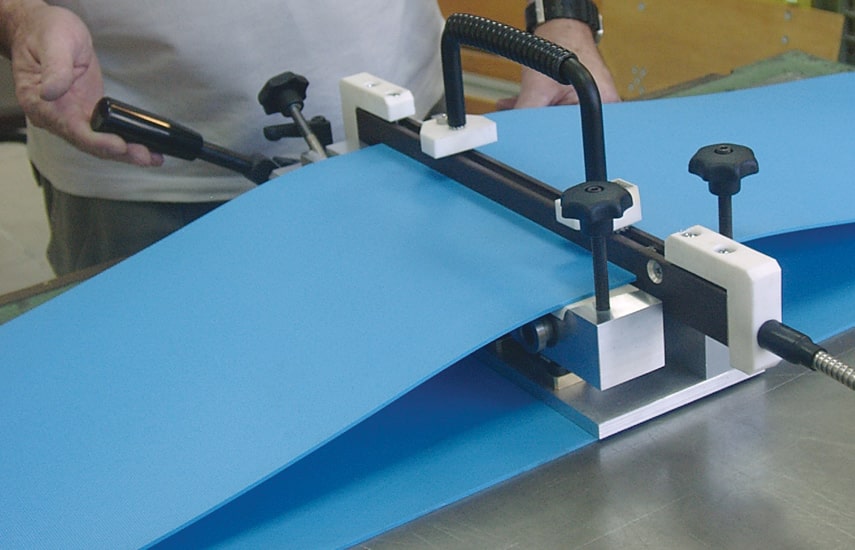

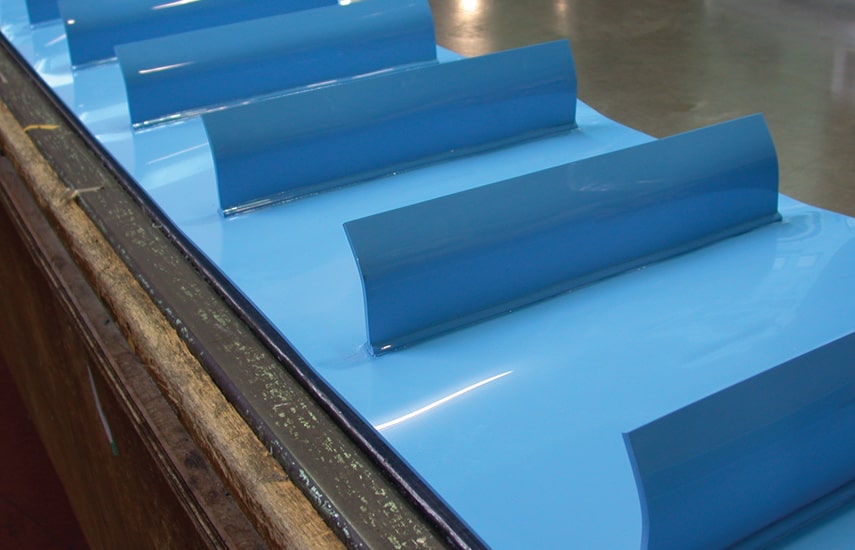

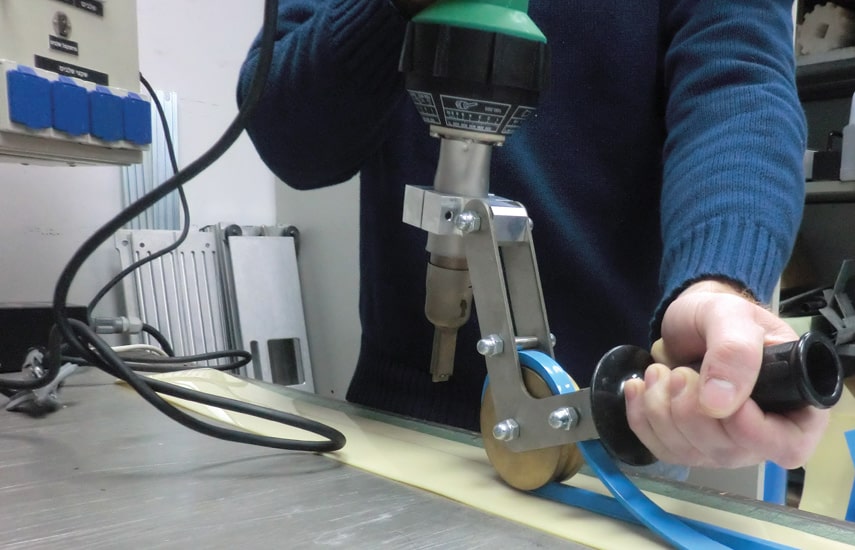

Volta supplies guides and sidewall material mounted on thin base belt for welding with hot air guns on dedicated jigs as well as with Volta hand tools.

Cleat or flight materials are supplied ready to weld in both flat and scoop versions. Flat ‘T cleats’ which have a small extended base are available and suited to older HF moulds.

Although Volta belts are generally butt-welded, generic mechanical joints can be used. A thermoplastic ‘Lace’ section is manufactured for use on food processing belts where metal or non-food grade fasteners are not accepted.

Electrodes

A small triangular profile, Volta ‘electrode’, is available for hand welding cleats and gussets and for repairing cuts and tears in belts. They are also available and used for welding belt joints on a Volta FT welder or for hand welding. Electrode is available in a variety of colors and hardnesses that correspond to our common belt types and in two sizes, (7 & 9mm). It can also be welded to form small projections on top of belts that work as mini cleats.

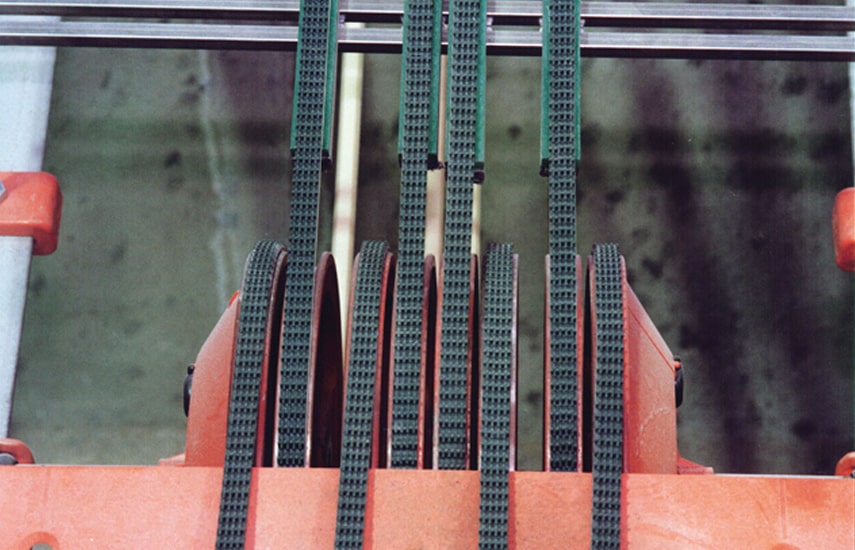

Coatings

Volta produces soft TPU coatings that are heat-welded onto other Volta products such as V profiles, timing belts and power belts. There are ranges of food-grade and non-food grade coatings with a variety of textures including foamed material, that change the coefficient of friction of the base belt or offer cushioning against compression. Their compatibility with heat-welding and their wear-resistant nature allows them to outperform rubber-based compounds which are stuck on with easily broken adhesive bonds and wear quickly.

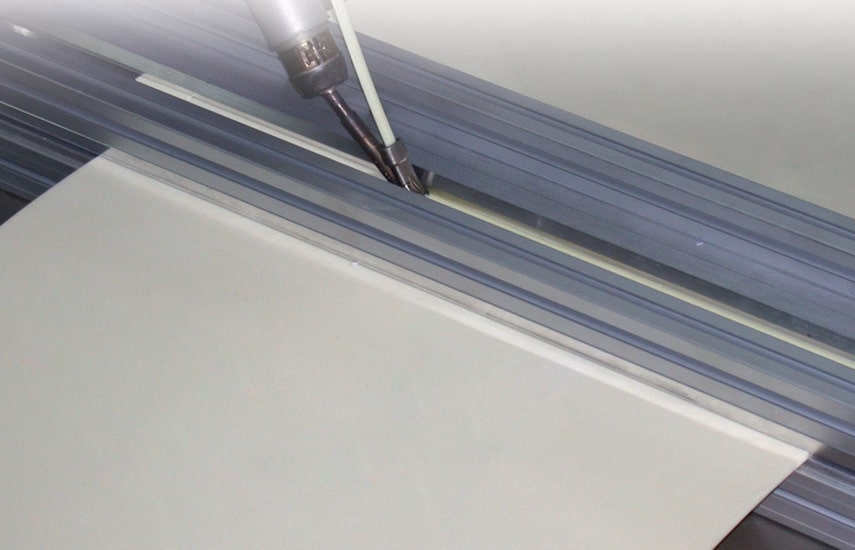

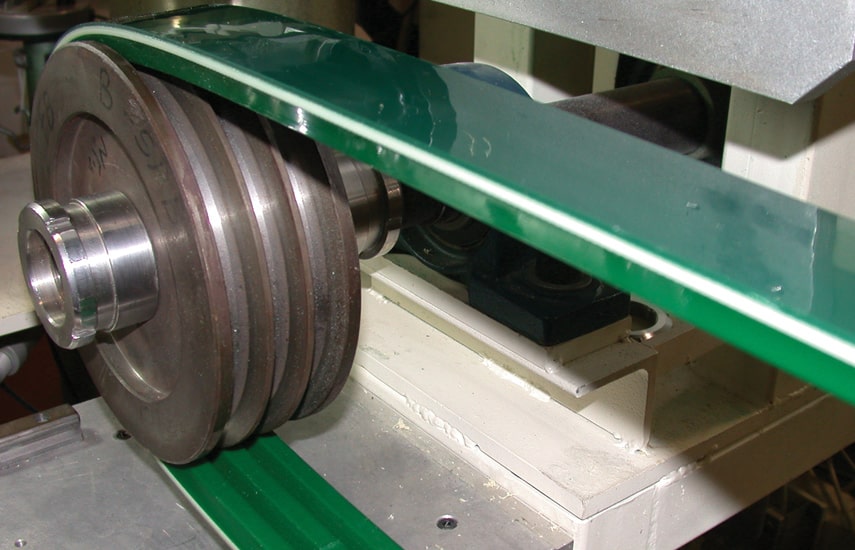

Roller Coating Sleeves

Volta has a range of hollow tubing or ‘sleeves’ in a range of diameters for coating steel rollers. A hand-operated devise is available which makes fitting an unskilled and quick work routine, requiring only compressed air. Sleeves can be used to dampen vibrations and protect damage to vulnerable fruit and vegetables or reduce noise levels and breakages with ceramic tiles after oven-firing.