The global seafood industry stands at a critical juncture. Racing toward $780 billion by 2030, this massive market faces a contamination crisis that’s forcing processing facilities to confront an uncomfortable reality: traditional conveyor systems are undermining food safety efforts.

The evidence is compelling. Over 2,400 seafood recalls have impacted the industry in just two decades. Most recently, Bornstein Seafoods recalled 44,550 pounds of shrimp due to Listeria contamination detected in their processing environment.

FDA data reveals that 20-32% of seafood facilities face compliance issues requiring corrective action, with pathogen control failures affecting nearly half of all inspections.

The root cause? Traditional fabric-coated belts and modular belts are creating bacterial contamination zones throughout processing facilities.

The Hidden Contamination Crisis in Traditional Belting

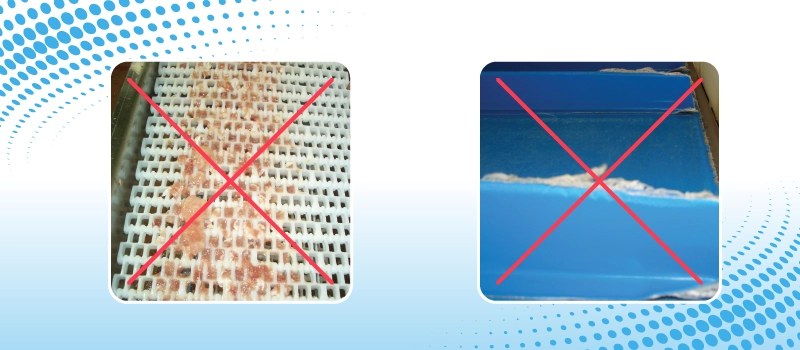

Traditional belting systems present serious contamination risks that standard cleaning protocols cannot eliminate. Fabric-coated belts and modular systems create areas of bacterial harborage that compromise food safety.

The technical reality:

- Fabric-coated belts are not hygienic because they fray, crack, and delaminate under normal use. Even light scratching can expose cavities and fabric layers, creating traps for bacteria and microorganisms that make cleaning and disinfection impossible. They are also not compatible with any sectors of food processing where wet washdowns are required.

- Modular belts are also problematic: their joints, pins, and link plates create over 30% extra surface area compared to homogeneous belting, that is hard to clean. Their moving parts can break or wear, and the hard plastic belt particles entering the food in process can harbor pathogens as well as potentially introducing foreign bodies where larger fragments detach.

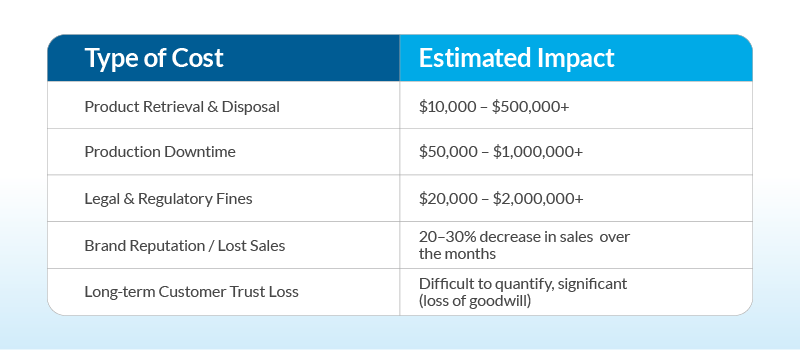

The Financial Impact of Contamination Events

Contamination events can be extremely costly for companies. Product recalls can cost up to millions of dollars for major recalls. Costs include retrieving products from market, disposal, production downtime, legal fees, and potential regulatory fines. Beyond direct costs, there are often long-term financial effects such as lost sales and lasting damage to company goodwill and the brand reputation. Proactively managing contamination risks can save significant money and protect both your bottom line and your brand.

Here’s an overview of potential costs associated with recalls:

Investing in modern, hygienic solutions is key to protecting your company from costly recalls and losses.

The Volta Homogeneous Technology Solution

Forward-thinking seafood processors are transitioning to homogeneous belting technology, which eliminates contamination risks at the source. Unlike fabric belts, homogeneous belts are constructed from monolithic thermoplastic elastomers (TPE) with no plies, fabric layers, or hinged modules where bacteria can hide.

Implementing Volta belts can save processors substantial costs in disinfection—but this is only part of the potential savings. Many Volta belts are installed on existing conveyors that remain unhygienic. While the belt surface in contact with food is improved, the presence of dirt traps on the conveyors is often overlooked. In many cases, processors are unaware of the hidden risks of continuing to use existing equipment without at least reviewing its condition.

There is now growing awareness of the dangers and potential costs of clinging to outdated or substandard equipment. Even recently purchased machinery can pose risks if not designed according to hygienic principles, and legal liability is usually measured against conformity with current state-of-the-art standards.

Key technology advantages:

Volta belts outperform conventional belt types for hygienic stability:

- Produced from dense TPE with resistant properties suited to difficult conditions: water, oils, fat, cold and freezing temperatures. The belts will not crack, delaminate or deteriorate over time.

- Smooth non-porous surfaces which prevent bacterial build-up and biofilm.

- Especially strong belts which can convey heavy loads, handle accumulation and take impact from problematic material and food waste without suffering damage from impact.

- Base materials are suited to Volta’s in-house hygienic fabrications while offer specialized conveying solutions.

- Easy to clean: no soaking, and keeping water consumption, and the use of other resources such as chemicals and even time, to a minimum.

The operational transformation is significant:

- Cleaning time reduced by 55% compared to modular belts, rising to 70-75% when the cleaning on the conveyor is reduced (less product seeping onto the frame).

- Where ply/synthetic belts are used, the saving is around 40% in disinfection resources and an extension of belt lifespan up to 8 times resulting from a superior mechanical performance, better resistance to cleaning and less cleaning.

Volta Belts – Compliant with Global Standards

Volta belts comply with EU, FDA, and USDA regulations and are consistent with EHEDG Guideline 43

See for Yourself: Volta Belt Applications in Action

Tuna Processing

- Long Lasting

- No bad odor

- Resistant to water, oil and chemicals

Under Water Conveying

- Smooth homogenous surfaces

- Available in all popular sizes

- Extremely Hygienic

- Customized perforations

Deep Freeze Applications

- Performs in sub-zero temperatures

- Pliable structure ideal for glazing lines

- Resistant to abrasion

Can Filling / Squeezing belts

- FDA/USDA/EU certified

- Available in Blue, Beige and Off-White

- Resistant to decay, rot and abrasion

Seafood processors face costly contamination risks from traditional fabric and modular belts, leading to recalls, downtime, and lost sales.

Volta’s homogeneous thermoplastic belts eliminate bacterial harborage, reduce cleaning time, and comply with global food safety standards.