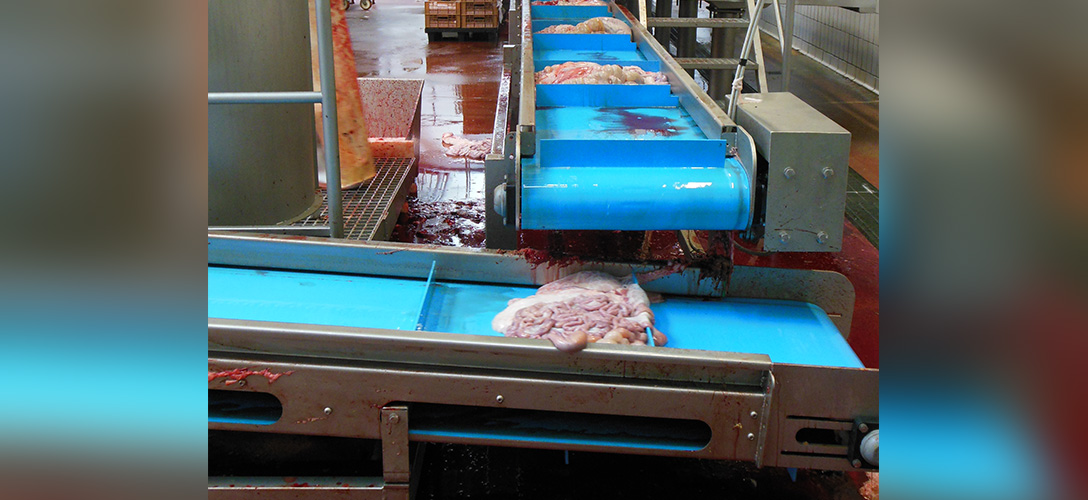

A newly equipped pork abattoir commissioned a set of conveyors designed with two flat belts that transferred offal at 90 degrees on a corner. The belts used synchronized compartments comprising of full width cleats, to keep each set of organs separate until the veterinary service on site had confirmed the meat as fit for consumption. The original design called for the belts to run through a hot water bath on the return to clean off possible pathogens that would contaminate the next load. After trials, it was clearly demonstrated not only that the system prevented leakages from each compartment onto the belt, but that cold water was enough to render the Volta SuperDrive™ belts ‘fit for use’ thus saving the energy required to heat the water and making the working environment safer. The factory equipped all its conveyors with Volta M material and saved on water and chemical consumption and labor required to clean. Similar options are made for beef abattoirs where closed compartments can be fabricated onto the base belt – this option gives a closed structure on all four sides and can be made in any length of width needed to accommodate different expected loads.

Improved Product Quality with FDR-DD-V1 Belts

Enhanced Efficiency & Quality – reduces cleaning time by 14 hours weekly and improves product quality with better containment and baseless sidewalls.