Home » Industries » Food & Hygiene » Confectionery

Confectionery

Volta supplies major producers of both chocolate products and candies. Conveying chocolate and cacao mass involves resistance to oils and fats. That coupled with sugar-coatings, hard-boiled sweets, abrasive sugar crystals and warm or sticky masses of coconut and other fillings, pose many challenges. We have developed retrofit procedures from stainless steel belts and supply many funnels and chutes for handling formed candies without damage. Round and trapezoid profile belts are used on enrobing lines where hygiene is paramount as the excess coating is returned to the process. We also design alternative solutions to bucket elevators.

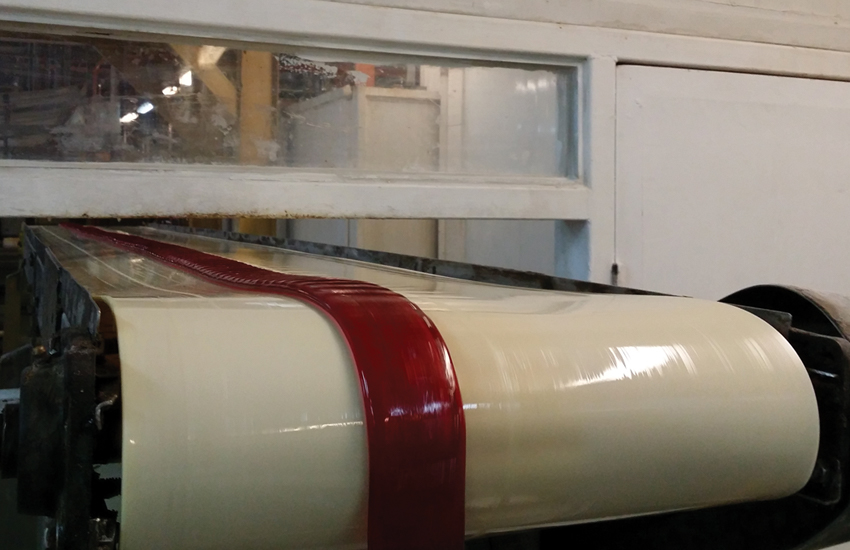

Molten candy extruded mass

Sticky warm candy mass is usually conveyed in narrow strips and conventional plied belts suffer damage from the continuous exposure to heat along that consistent strip. This is accelerated by the effect of cleaning chemicals on this area and the plastic soon delaminates, leaving open fibres in contact with the product. We have been challenged by leading manufacturers of hard candies to refit thermoplastic belts on this application. There is no damage from the heat and belts work without any elongation providing a perfect solution for the industry.

Cocoa powder infeed

A multinational company with a chocolate factory located far from reliable belt service centers, called a Volta OEM partner in to review a long cocoa powder incline conveyor. The conveyor system was outdated and was a drain on the annual maintenance budget demanding constant supervision and repair. A site visit was arranged, and an assessment was made of the best economic alternative. SuperDrive™ was selected without any need for cleats or a texture. Three additional SuperDrive™ belts were supplied to complete the off-loading and supply to the next process. A similar installation made at another producer on a drinking chocolate line increased belt life from 8 months to 8 years.

Sugar coated jellies

Sugar coating is common on soft jellies to prevent sticking. The product remains inherently sticky and the sugar releases a loose abrasive grit onto the machinery when handled in bulk. Volta was given the challenge of developing a solution for both issues and fabricated a 2” pitch DualDrive™ belt to replace the modular one that was clogged with product residue. A roof top texture was utilized on both the belt and the cleats to prevent adhesion as well as reducing the abrading motion between the sugar-coated product and the belt