Home » Positive Drive » Mini SuperDrive™ (MSD)

Mini SuperDrive™ (MSD)

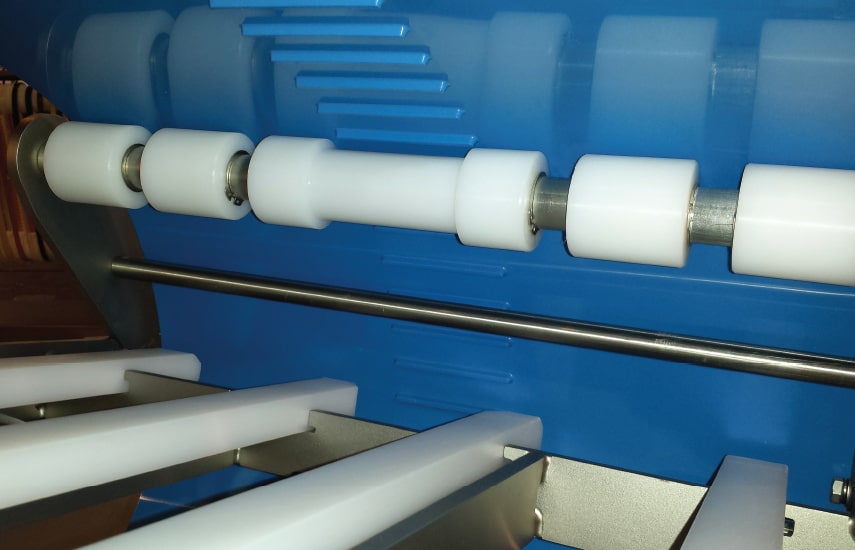

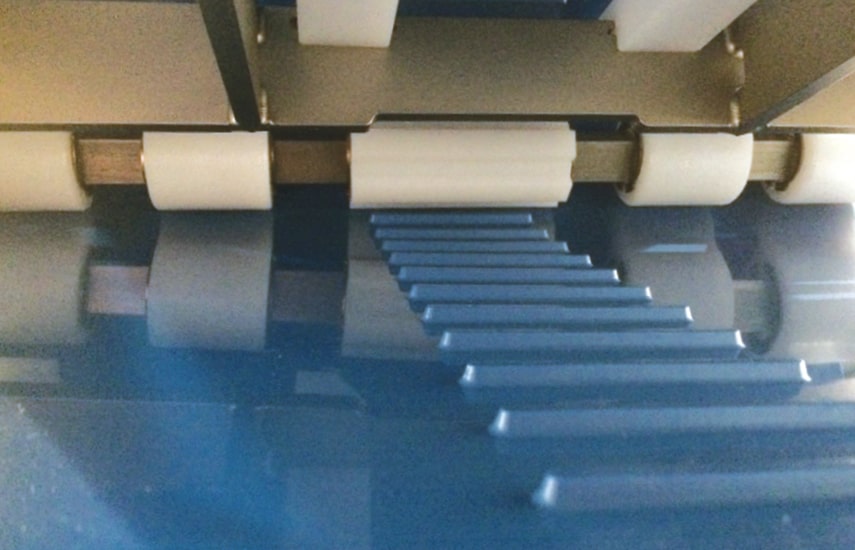

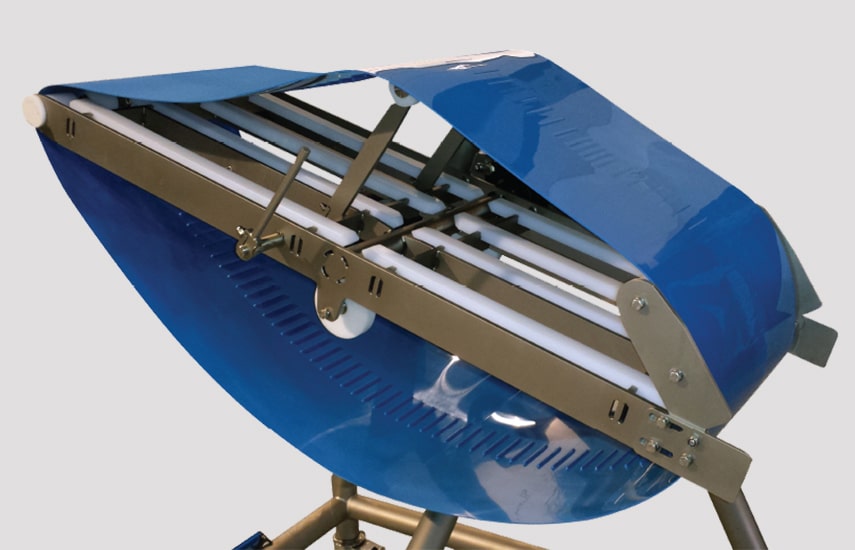

Volta’s Mini SuperDrive™ (MSD) complements Volta’s positive drive belt range by offering the advantages of the heavier SuperDrive™ range in a smaller tooth profile format. The Mini SuperDrive™ belt solves the key mechanical problems of classic flat belts, namely, slipping and off-tracking. The teeth on the underside of the belt engage with the drive pulley and provide an unvarying, smooth conveying and transfer of product with no belt pretension required. The homogenous structure works smoothly and silently with minimal strain, thereby extending belt life and saving wear and tear on bearings and other conveyor components.

Technology

The teeth are guided by and contained within, wear strips on the belt carry-way and grooved tail end pulleys which combine into a simple tracking system that requires no additional elements that would otherwise add to the conveyor construction and price. OEMs around the world use this feature to reduce conveyor costs and provide competitive and long-lasting food processing conveyors. The same features also enable a saving on ownership costs.

Advantages

Mini SuperDrive™ is manufactured from high performance, food grade TPE/TPU materials in several finishes that enable it to be used in thousands of applications with a pulley diameter of at least 48mm. This flexibility also makes it well-suited to center drive designs and tight transfer conveyors. Apart from the formidable mechanical advantages offered, the most beneficial impact is seen in food processing where direct contact with food in all its stages of production raises hygienic concerns and exposes food to potential contamination.

Hygienic Solution

The demand for food grade belts has led to a huge variety of belt types in the marketplace, making the choice difficult for a processor who has specific requirements and must work efficiently and on budget. Guidelines are emerging which often find it easier to describe what is not hygienic but there is agreement that homogenous belts are the most hygienic conveyor belt option. Together with the additional mechanical advantages of positive drive and self-tracking, it is the best choice for compact hygienic conveyors and for upgrading existing 1” pitch modular belt conveyors.

Conveyors

Are you looking for a solution?

Learn from our experience

An Asian customer was happy to work with an established Volta distributor and fabricator

Large scale producers of cheese and dairy products must contend with a fermented product that is sold in blocks, sliced, soft or hard and often is sold as an ingredient like grated cheese.

A large turkey processor made a side-by-side comparison of Volta SuperDrive™ and conventional modular belt.

A leading European producer of poultry sausages and smallgoods uses Volta extensively on over 50 conveyors.