Home » Industries » Industrial Applications » Ceramics & Roof Tiles

Ceramics & Roof Tiles

The solutions we have developed with our partners are built on decades of accumulated knowledge with thermoplastics. Many manufacturers understand that conveying systems can be an economic burden on the cost of ownership. Frequent belt changes and the resulting costly down time coupled with the increasing service costs and difficulties of bringing outside contractors on site, are all reasons to consider a different, more economical approach.

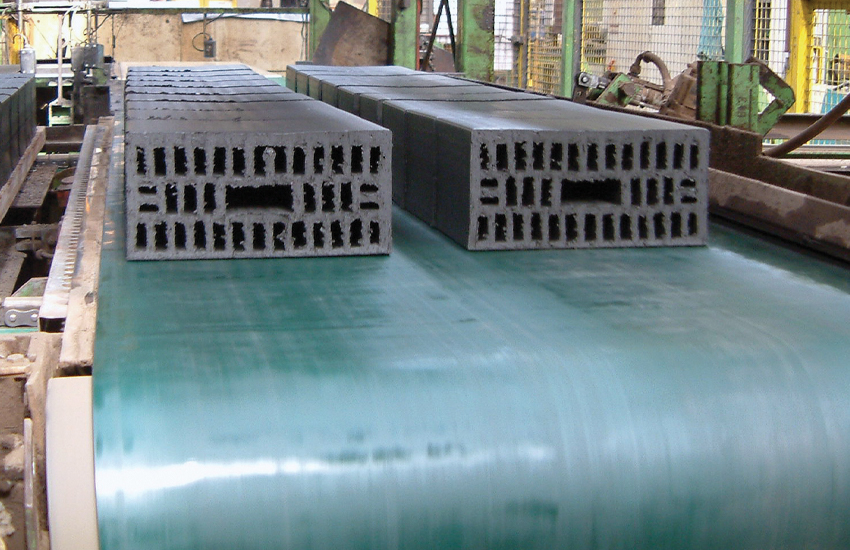

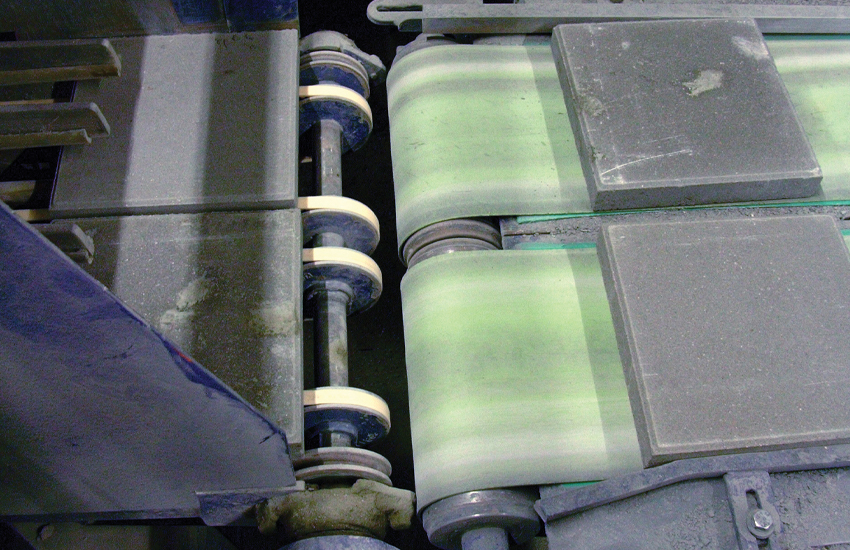

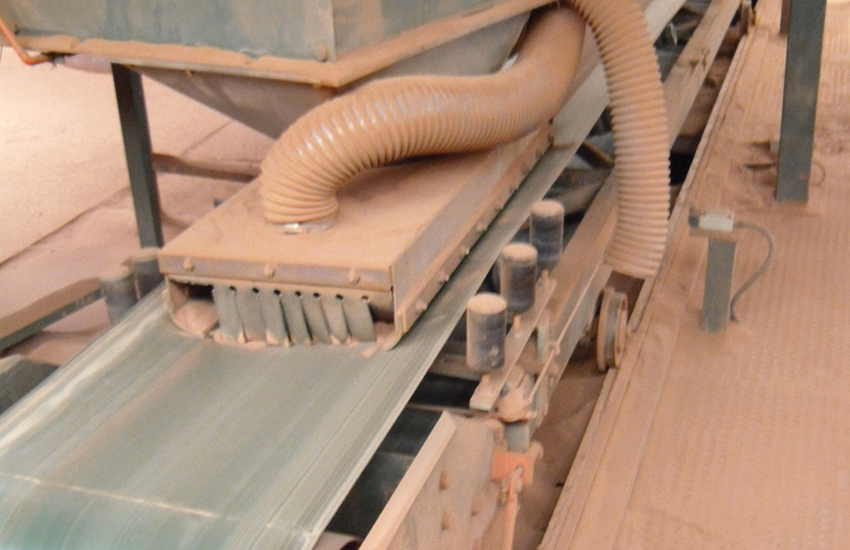

Ceramic tile lines, flat belting, troughs, and elevators

Production lines of building materials are high output with little time for breakdowns. The products are highly abrasive and traditional fast-wearing rubber belts release belt fragments into the powders and clay used as raw materials. Volta equips many ceramic tile and roof tile companies with round, V and flat belts as well as fabricated flat belts to provide long-lasting solutions that eliminate contamination of powders and carry tiles with limited wear and tear. Long, steep elevators can use Volta positive drive belts where breakdowns involve days of maintenance and repair work.

Profile belts

Profile belts are the backbone of ceramic, roof tile and brick conveying. Volta has developed the most comprehensive range of options available based on cooperation with the world’s leading OEMs. Special profiles are available for glazing lines, stop-start operations, corner transfers and a revolutionary wear-resistant profile range for handling the most difficult materials. The profile belts are renowned for having exceptional dimensional integrity which prevents vibration resonance common to cheap generic products and resist elongation. For over 50 years this range has been the brand of choice for the industry.