Home » Industries » Food & Hygiene » Fish & Seafood

Fish & Seafood

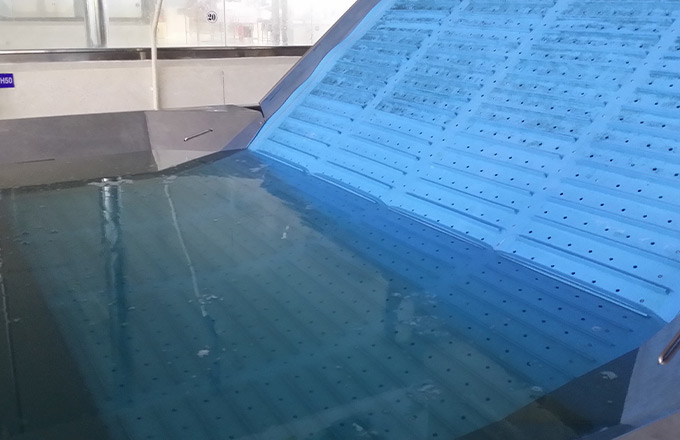

Fish and seafood of all types are very prone to contain bacteria and are considered amongst the most dangerous foods to process. Many varieties are also harvested or fished in contaminated water. This increases the risk of cross-contamination in the processing facility and makes the use of Volta thermoplastic belting material the safest choice. It also saves on costs of ownership by reducing water consumption and cleaning times. Perforated washing belts are common and hole sizes and shapes can be suited to the conveyor, thereby reducing belt cost, and maximizing belt strength.

Shrimp sorting and washing retrofit

Shrimps and prawns form the backbone of several developing economies and factory processing is geared to supplying the growing export demand. This means that auditors are examining the factory with greater scrutiny and conventional modular systems that cannot be cleaned adequately are constantly being rejected or noted as hazards. We work with many local engineering companies to refit existing machinery and provide custom-made perforations to give the desired level of drainage while avoiding product particles getting trapped in the holes.

Abrasive seafood environment

Fish and seafood can present belt suppliers with some of the most difficult challenges in food processing. Seafoods are highly susceptible to deterioration when handling. They must be processed quickly and kept at low temperatures. Volta has developed belting materials with enhanced resistance to a host of ambient conditions such as CO2 mist and water as well as hot or frozen products. Our compounds inherently resist the extremely abrasive nature of everything from frozen breadcrumbed fillets to shellfish. Oysters embedded with sea grit present their own specific challenge. Even though Volta is a completely thermoplastic belt, mussels transferring from a cooking process at over 90 degrees Celsius (194 Fahrenheit) is possible while maintaining proper tension.

The big fish industry

Fish industries like tuna, salmon and herring supply a huge world demand and have required specific industrial solutions and processing systems. Volta belts guarantee reliable safe conditions for raw filleting and do not suffer from mechanical breakdowns during shifts which would hamper throughput. The flexible material makes this difficult working environment better by reducing noise levels. Most lines work on tiered conveyor systems and the use of Volta belts on waste lines reduces the risk of cross-contamination.