Home » Positive Drive » DualDrive™ (DD)

DualDrive™

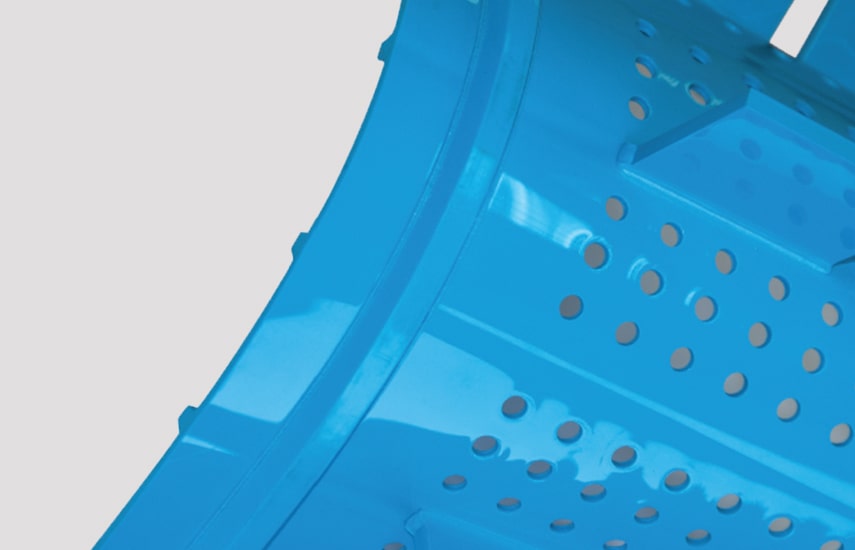

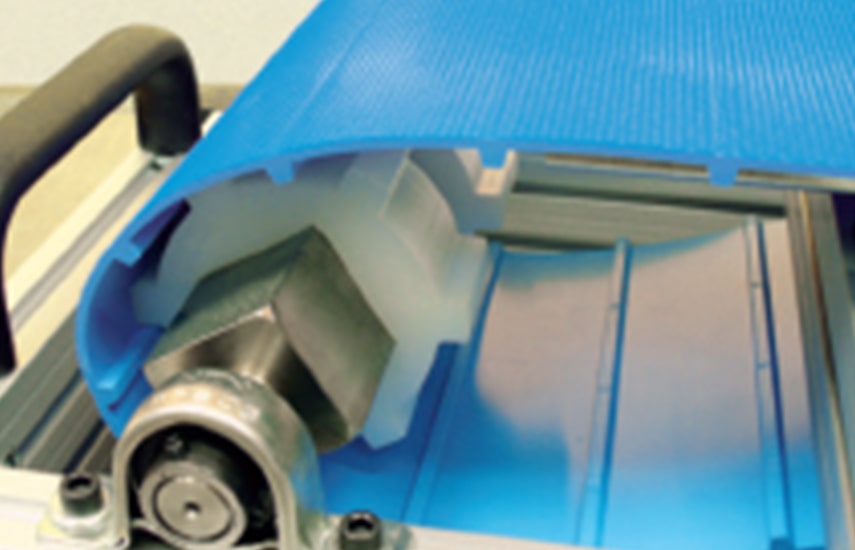

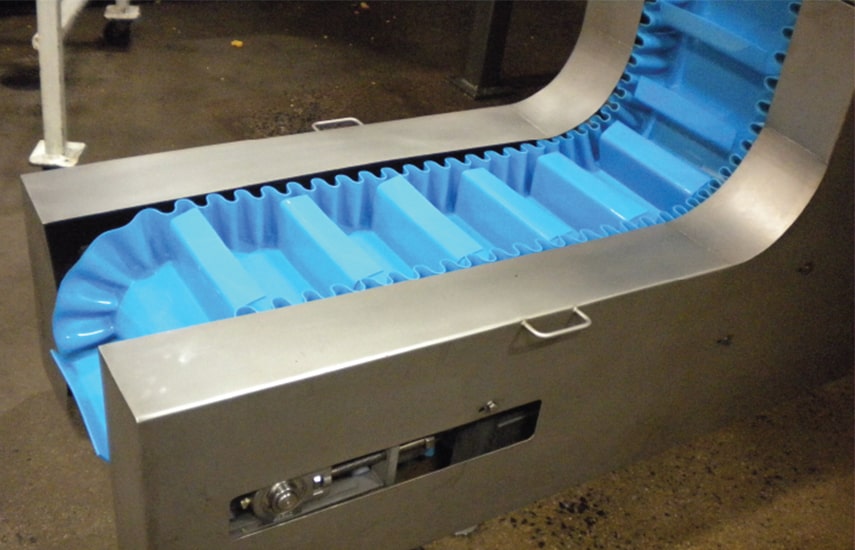

DualDrive™ is a fully extruded positive drive belt featuring a smooth homogeneous character and integral teeth on the drive side which can act as built-in cleats.

Material Features

Rigid lateral design design

Budget retrofitting from 2”

pitch modular systems

Reduce running costs - more time for production

Superior material quality - lower bacteria counts-cleaner product

Uses reduced capacity motors and zero or low pretension

Multiple textures in various thicknesses

Advantages

DualDrive™is manufactured from high performance, food grade TPE/TPU materials and is designed to replace 2” pitch modular belts with a minimum retrofit. Its ease of installing as a conveyor belt replacement can be seen in some of the case studies on this website and it is a value-added food grade conveyor belt for processors seeking to reduce the cost of ownership. It can be used wherever there is direct contact with food in all its stages of production to reduce the potential for contamination.

Hygienic Solution

The demand for food grade belts has led to a huge variety of belt types in the marketplace, making the choice difficult for a processor who has specific requirements and must work efficiently and on budget. Guidelines are emerging which often find it easier to describe what is not hygienic but there is agreement that homogenous belts are the most hygienic conveyor belt option. For companies unwilling to invest in new conveyors, the conversion from old modular technologies to hygienic thermoplastic belting can be done on a convenient limited budget with DualDrive™.

Conveyors

Are you looking for a solution?

Learn from our experience

The snack food market is a global market. The main consumers reside in Europe and North America.

The fourth most important food crop worldwide is potatoes. 60% of the processing is handled in the most industrialized countries.

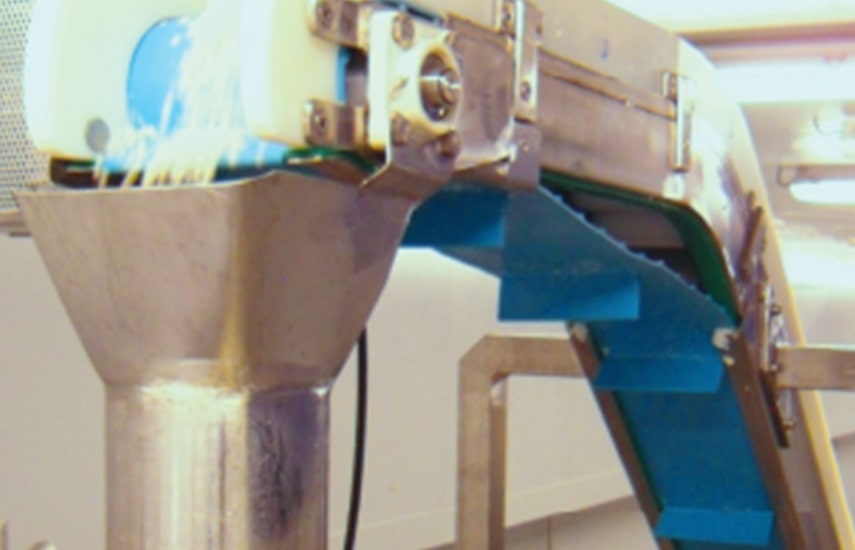

In this factory, eight incline conveyors transfer frozen fruit pieces to a horizontal conveyor.

Powdered milk is a key product in many countries. It fills the gap where local farms do not supply all the needs of a given market.